1. Process route

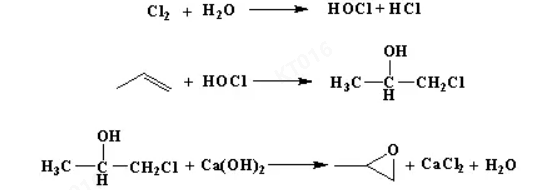

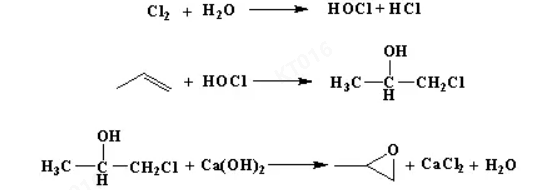

Chlorohydrin method: Using propylene, chlorine gas, and calcium hydroxide (or sodium hydroxide) as raw materials, epichlorohydrin is produced through chlorohydrin and saponification reactions. The reaction equation is:

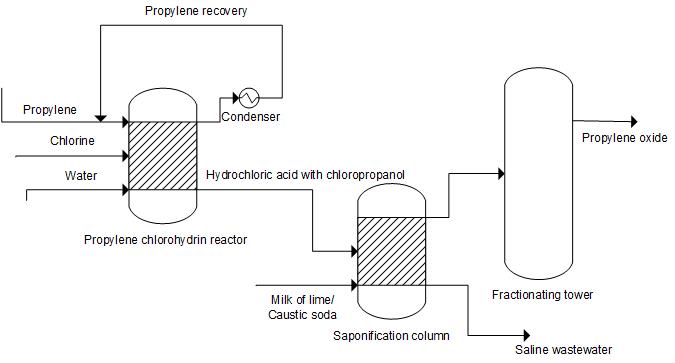

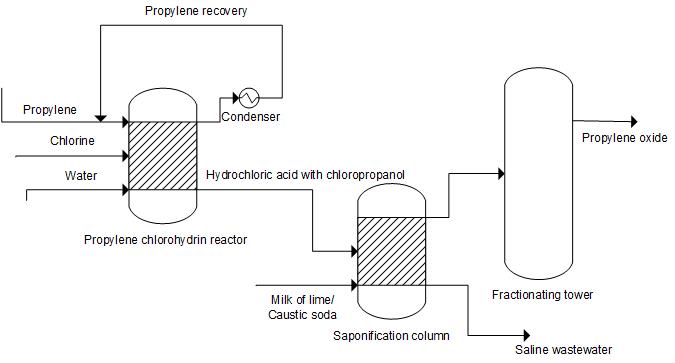

2. Process flow

3. Technical advantages

Shandong Jereh Catech Technology Co., Ltd. has the advantages of mature technology, short reaction process, low purity requirements for raw materials, and low investment in the production process of chlorohydrin.

4. Downstream market direction

The downstream application of epoxy propane is very extensive, roughly divided into the following product routes:

① Epoxy propane → Polyether polyol → Polyurethane soft and hard foam, high rebound, POP type;

② Epoxy propane → propylene glycol methyl ether and dimethyl carbonate → epoxy resin and polyurethane resin;

③ Epoxy propane → Propylene glycol ether → Organic solvent, alcohol ether acetate;

④ Epoxy propane → Other uses → Active agents, flame retardants, emulsifiers.

中文

中文