1. Process route

The oxidation dehydrogenation method of butene, the reaction equation is:

C4H8+1/2O2 → C4H6+H2O+126KJ/mol

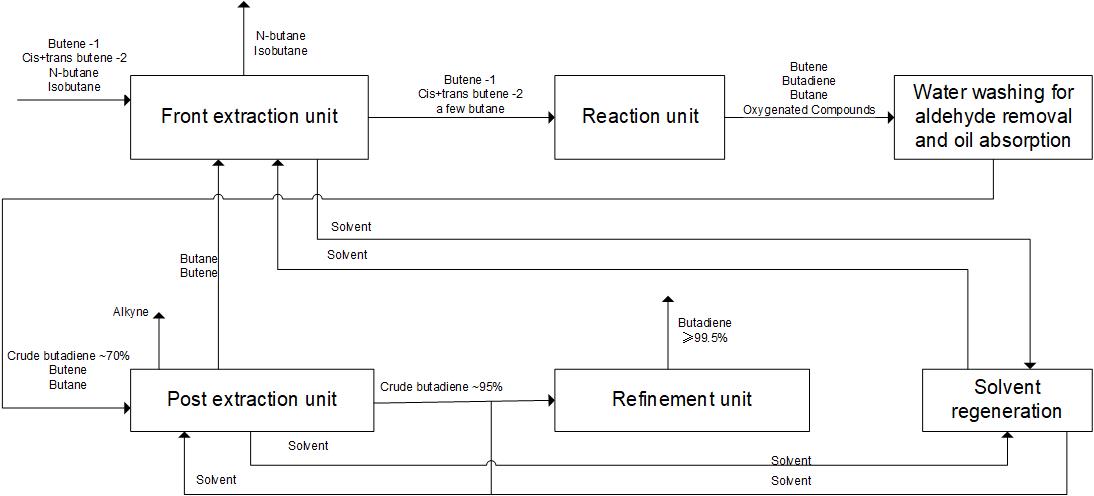

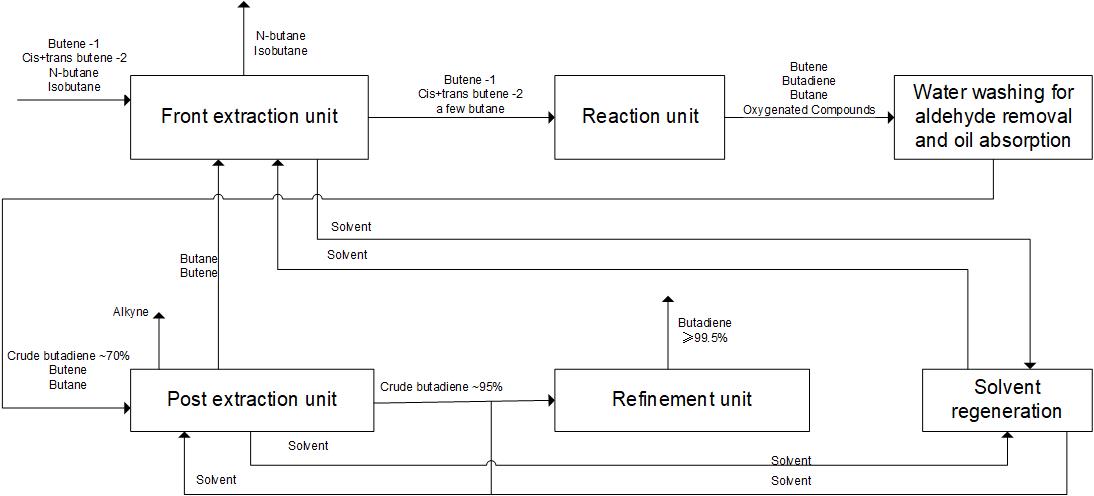

2. Process flow

3. Technical advantages

① Stable performance, high operational safety, and mature technology;

② Less three wastes, easy to handle;

③ High selectivity and conversion rate, with few side reactions;

④ Independent research and development of catalysts, with less catalyst coking;

⑤ Low energy consumption and low investment.

4. Downstream market direction

The downstream application of butadiene is very extensive, roughly divided into the following product routes:

① Butadiene → synthetic rubber (such as butadiene styrene rubber, chloroprene rubber, butadiene rubber, nitrile rubber, etc.), with the largest application proportion;

② Butadiene → resin (ABS resin, SBS resin, BS resin, MBS resin, etc.);

③ Butadiene → 1,4-butanediol (engineering plastic), adiponitrile (nylon 66 monomer), sulfolane, anthraquinone, tetrahydrofuran, etc.

中文

中文